The scenario

At half past three Liz started to drink her first hot drink of the day. It was 15 years ago today that she had joined the practice, but it had never been as busy as it was now.

As the steaming brew started to reduce her stress levels, Sue rushed in.

“Sorry Liz, three clients are waiting for call backs and your first appointment is in 20 minutes. Oh, and have you seen this? Practice Standards are asking us to do environmental sustainability! Great idea, but we have so much to do already!”

“Don’t worry Sue, I will have a look tonight,” she said, bringing the mug to her lips again.

Scrolling through Veterinary Voices on her phone that night, Liz came across a post on environmental sustainability, ‘Oh yes, I must investigate that!’ She thought. She went to the PSS website and it didn’t seem too bad: not over-ordering stock, using anaesthetic gasses less, taking back unused medicines from clients.

But it got Liz thinking – What is sustainability? She googled it:

“Sustainability consists of fulfilling the needs of current generations without compromising the needs of future generations, while ensuring a balance between economic growth, environmental care and social well-being”.1

‘Is what we’re doing in our practice now, really sustainable?’ she wondered,

‘Running around in circles, everyone exhausted… there must be another way?’

She researched the topic more and at the top of the page, there it was: Lean in Healthcare. ‘What on earth is Lean?’

“Lean is focused on making work more efficient by looking at the various types of waste in our practice.”

This felt exciting. ‘Yes, of course, there is more than one type of waste and Lean is about cutting out any waste in the system, whether that be physical waste, wasted time, wasted energy, or ideas – like suggestions – that don’t get followed up. YES! It’s ALL waste!’

She started to understand about Lean philosophy too:

“Reducing waste can only happen through a continual dialogue with our team – talking with them, and really listening to their ideas. These ideas are key to a Lean approach – they are like the foundations of a house.” She decided, with a little bit of effort, they could cut down waste, involve the team more, and the practice could enjoy some cost savings too!

She scratched her head, ‘But, could Lean really work for us? A couple of our nurses are into green issues, maybe they would be interested?’

She read more about Lean, but her real breakthrough came when she found a resource on the RCVS Knowledge website.

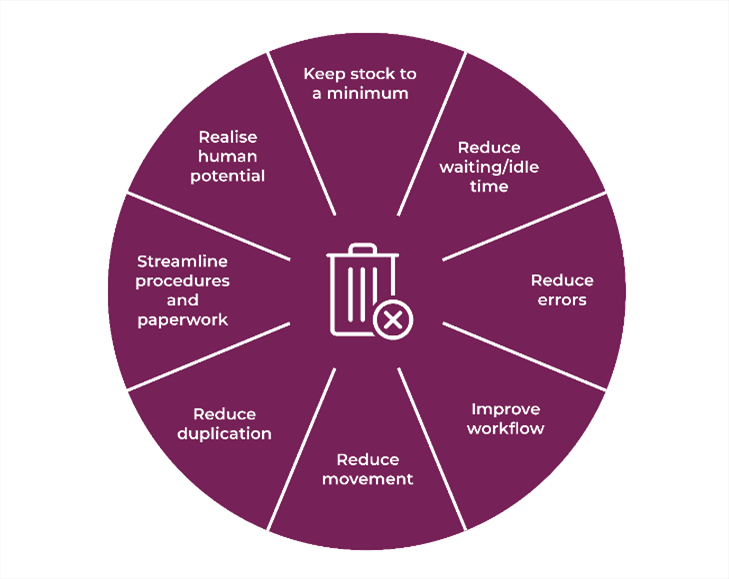

The principles of Lean

There are eight principles of Lean, here we will consider how these can be applied to veterinary practice to reduce waste and improve the quality of care.

1. Keep stock to a minimum

Liz planned a meeting with the nurses who’d expressed interest in recycling to explore how this would work and any potential knock-on effects after changes are made. This group would be empowered to make changes, audit the waste reduction, and then take the project forward.

2. Reduce waiting/idle time

Reception could lead on client waiting times and the organisation of appointments – they know exactly where the bottlenecks are (e.g., 5pm when multiple vets are consulting, but discharge appointments need to be fitted in.)

The team could also look at any waiting time (idle time) earlier in the day, e.g., during the operating schedule: discussing the order of procedures daily in a morning huddle might help. This would also relieve pressure on the team later on in the day.

3. Reduce errors

Here the benefit of a Lean approach was clear. By driving down the frequency of accidents, patients and clients and the practice would benefit in equal measure. They would ‘waste’ less time addressing complaints and the dedicated team would feel less burdened by the stress that invariably follows.

Keeping a list of everything that goes wrong – including near misses – would be a great start. These could be discussed by everyone to understand why things happened as they did, and what could be changed to reduce the chances of the same scenario happening again. This would free time to discuss interesting cases more regularly, and start a cycle of learning and improvement for even better standards of care. One of the vets was interested in quality improvement (QI) and had suggested running significant event audits but Liz had said, post-pandemic, it wasn’t her top priority. Perhaps now was the time to revisit that?

4. Improve workflow

Liz could see this was about planning their time better, e.g., avoiding three vets needing the x-ray room simultaneously.

5. Reduce movement by having supplies readily accessible

Liz could remember a locum suggesting they make up kits for certain procedures – e.g. chest drains -with everything needed kept together in zipped folders, along with laminated instructions. Nurses and vets would spend less time wasting their ‘movement’ looking for items – this could improve the efficiency of the system overall too.

6. Reduce duplication

Not repeating tests or imaging already done at a previous practice, unless clinically indicated.

7. Streamline procedures and paperwork

Oh, for a practice management system where clients’ and animals’ details are captured once, then everything else is filled in automatically! Something to work with head office on.

8. Realise human potential

The practice could waste less of the team’s amazing potential, and even further develop it. Of course, in the past time had often been the problem but Liz now understood the power of Lean – by saving time elsewhere in the day, she might capture regular periods during the working week to spend with them. What could they do more of as a unit? Learn together, make improvements to patient care, the possibilities were endless.

Fifteen years had gone in a flash. It had been hugely enjoyable and rewarding work, but also sometimes demanding. Liz felt she was in a good position to talk from experience with her team about the stresses and strains of caring for animals. But with Lean, she now felt they had a framework to change things – not just for themselves, but for patients, clients, and the environment too. True sustainability was feeling just that little bit closer.

Checklist: what you can do next

- Stream the free to access CPD session on ‘The role of improvement science and QI in reducing waste in veterinary healthcare’, and read our previous QI Feature ‘Lean into change’ to discover more about how Lean can benefit you and your teams.

- Take the free CPD sessions on reducing medicine associated waste. Visit ‘Sustainability in the dispensary’, by Ann Lawson, Senior Assessor for the RCVS Practice Standards Scheme and ‘Storage of Medicines’, by Lee Grist from the Veterinary Medicines Directorate.

- Streamline procedures through care bundles, a group of evidence-based practices and resources that relate to a disease or a set of symptoms that help to save time, promote teamwork, and improve patient outcomes when implemented altogether. Find out more from Helen Ballantyne, dual qualified medical and veterinary nurse.

- Listen to Alice Bird, former Senior Clinician in Anaesthesia at the Animal Health Trust, talk through the system they used to reduce errors in a non-confrontational way. Delve deeper by using the free Significant Event Audit tools and resources.

- Read the Highly Commended Knowledge Award-winning case example on how a team reduced unnecessary movement by creating a BOAS Box.

- Realise your human potential. Challenge the status quo if something isn’t working for you. Quality Improvement provides us with a method to do this and to be empowered to feel that we can make change for ourselves. Listen to Angie Rayner, Director of Quality, CVS, and Mark Moreton, Hub Lead, CVS, talk about an evidence-based framework to take this forward.

References

- United Nations (1987) Report of the World Commission on Environment and Development: Our Common Future [Brundtland Report] [online]. Available from: http://www.un-documents.net/k-002988.htm [accessed 10 March 2023]

About the authors

Pam Mosedale BVetMed MRCVS

Pam is QI Clinical lead for RCVS Knowledge and Chair of the RCVS Knowledge Quality Improvement Advisory Board. She was Lead Assessor for the RCVS Practice Standards Scheme until very recently. Pam has worked in first opinion practice for most of her career. She is also an SQP assessor for AMTRA and edits the BSAVA Guide to the Use of Veterinary Medicines and organises the BSAVA Dispensing Course.

Pam has been involved in establishing Quality Improvement resources for the veterinary practice team. She is passionate about QI becoming part of the normal working day for veterinary teams and contributing to a just learning culture in practice.

Mark Turner BVSc MRes MRCVS

Mark graduated from the University of Liverpool in 1996 and in 2017 completed a Masters degree at the RVC investigating patient safety culture in the UK veterinary professions.

The research project investigated contemporary knowledge of patient safety behaviours in practice including significant event reporting and auditing.

He has an interest in the application of patient safety as a tool for improving staff engagement and success. He has written for Vet Times, Companion magazine and appeared as a guest blogger for the BVA/RCVS Vet Futures project.

You might also like

-

Long read

-

Long read

-

Long read1 January 2024

Culture eats glitter for breakfast